The Manufacturing Process Of Carbon Rims

Jul 12 , 2021GoFast Bicycle represents the latest technological advances in carbon-fiber bicycle rim performance products. Engineered from the trail up to be lighter, stronger, faster and more aerodynamic.The production processes are as follows:

Prepare Material-> Layup-> Molding-> Drilling-> Polish-> QC Check-> Packing

Prepare Material:

Every part, including the rim serial number, air bladder and carbon prepreg is gathered, inspected and weighed to verify everything is accounted for.

Layup:

Each rim requires between 30-40 layers of carbon fiber prepreg. Our most experienced workers apply the prepreg by hand and the process takes 30-45 minutes for most rims.

Molding:

We use the latest generation of machinery to achieve the most stable temperature and air pressure throughout the heating, curing, and cooling process. With careful control of all aspects during the ~45 minute cycle, we can make rims with a flawless finish.

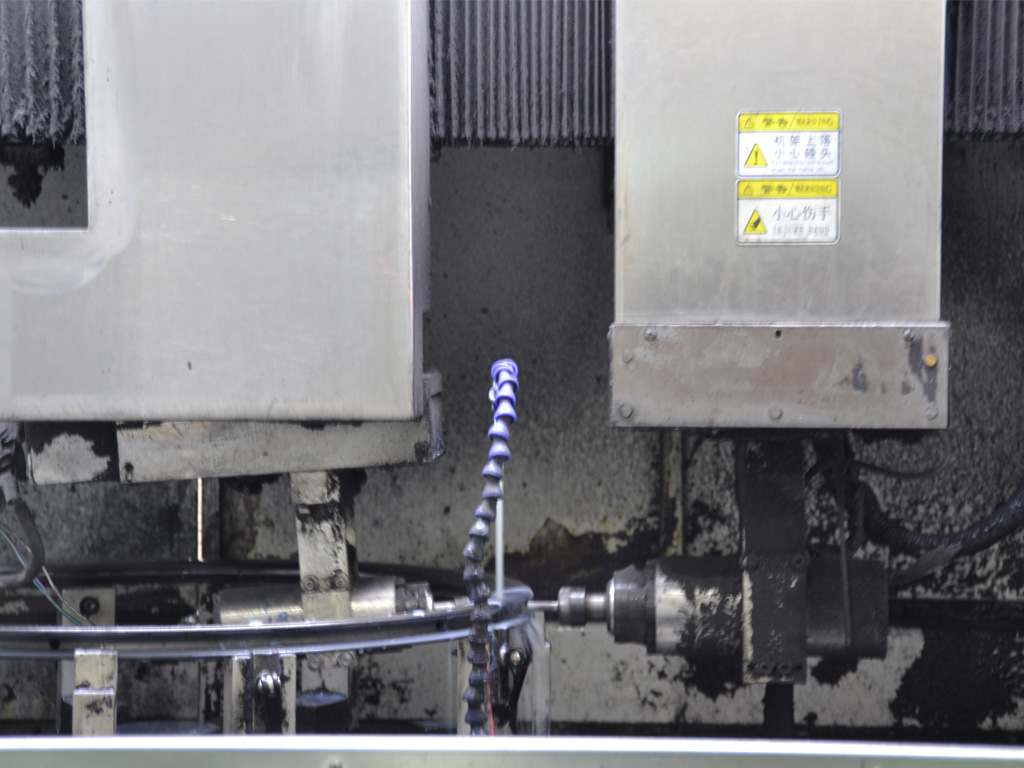

Drilling:

All rims are drilled with a high speed CNC machine. It is a computer controlled drilling machine which customizes each spoke hole to an exact position and angle.

Polish:

Extra resin that has wicked away during the curing process is removed, and the spoke holes are deburred.

Finishing:

Rim graphics are applied, and a clear coat is applied (if applicable to protect waterslide decals). Glossy, Satin, and Matte finishes, and customized graphics are available.

QC Check:

In additional to the standard QC check, we also check roundness (must be within 0.2mm), flatness (within 0.15mm) and with some products the tire pressure check is performed.

Packing:

Products are packaged well to avoid damage during transit, and items are cross referenced by the order ticket to make sure no parts are missing.